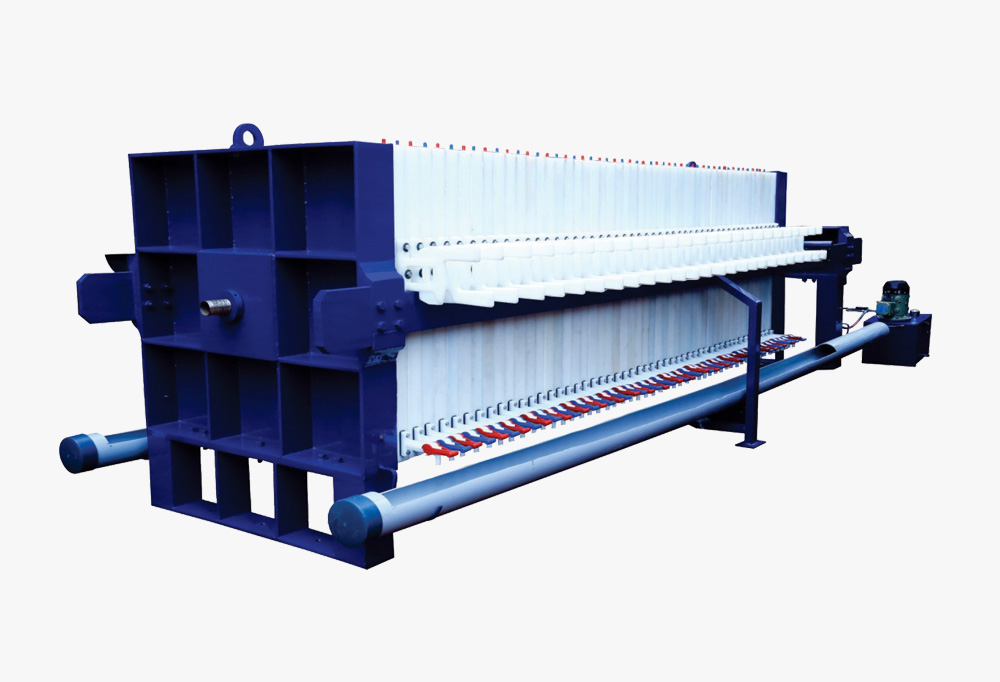

A filter press is a series of filter plates which are pressed together by hydraulic ram or manual screw tightening mechanism.

The filter plates are built with a cavity or space in between them where the filter cake is formed.

First the plate press is filled with the slurry until all of the aforementioned spaces are full. Once the slurry takes up all the space in between each of the plate press chambers, valves are opened on the bottom corners of the filter plates to allow the filtrate to escape as more and more slurry is pumped in.

Eventually the slurry cannot be pumped in because filter cake occupies all of the spaces in between the chambers. At this point the filter plates are separated either by mechanical or manual means, usually one at a time, allowing the filter cake to be discharged.

The filter cake then be collected in collection tray or by hopper system for collection & discharge.

The Vasu Pharmatech Filter Press is ideal for sludge dewatering applications where dry cake solids are a key priority. Filter press can achieve dry solids from 50% – 80% depending on the nature of sludge, and is easily customized to suit all dewatering and solids capture requirements.

The operating costs are also minimized due to very low consumption of both polymer and energy.

Our filter presses offer unrivalled quality, integrity and engineering excellence in a robust design that also includes full operator safety protection.

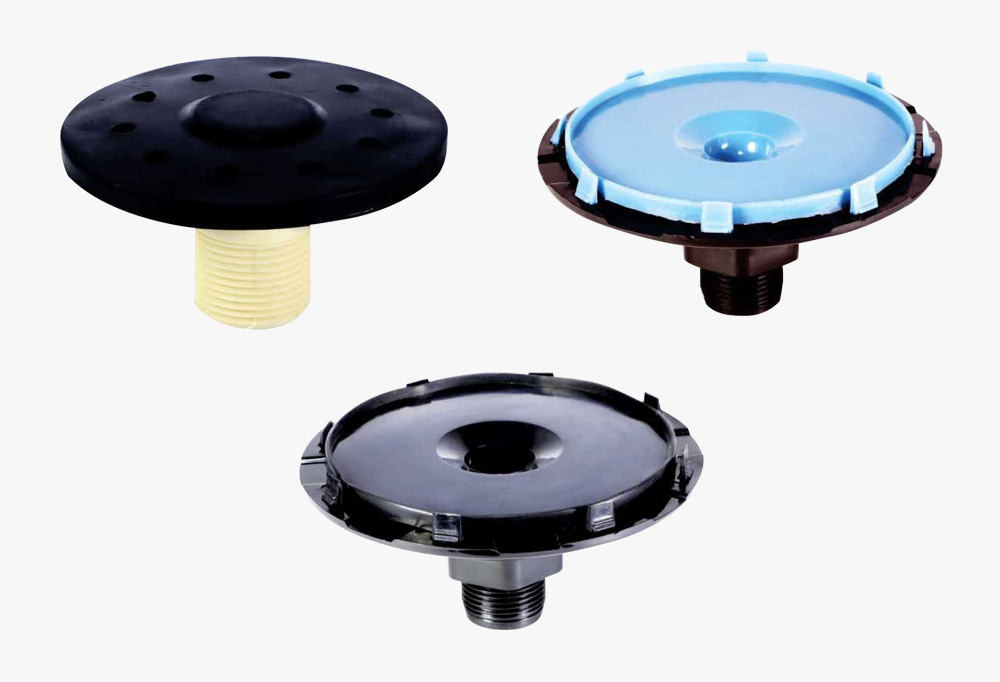

The filter press plates are available in recessed type and structure is made up of either Mild Steel or Cast Iron to withstand the standard feed pressures of 3Kg – 6Kg.

Our filter presses help to reduce the environmental footprint from water and waste streams, by maximizing reuse of water and by minimizing energy consumption and waste.

FSC India.

FSC India.