To supply the required oxygen to the metabolizing microorganisms.

To provide mixing so that the microbes come into intimate contact with the dissolved and suspended organic matter.

The two most common aeration systems are subsurface and mechanical. In a subsurface system, air is introduced by diffusers or other devices submerged in the wastewater. A mechanical system agitates the wastewater by various means (e.g., propellers, blades, or brushes) to introduce air from the atmosphere.

Generally submerged bubble aeration provides more effective result than surface aeration.

In the primary and secondary treatment of wastewater, it is common to use aeration as a method of removing organic matter. Submerged bubble aeration works effectively by diffusing small air bubbles to mix with the wastewater and facilitate the work of aerobic bacteria in breaking down organic waste.

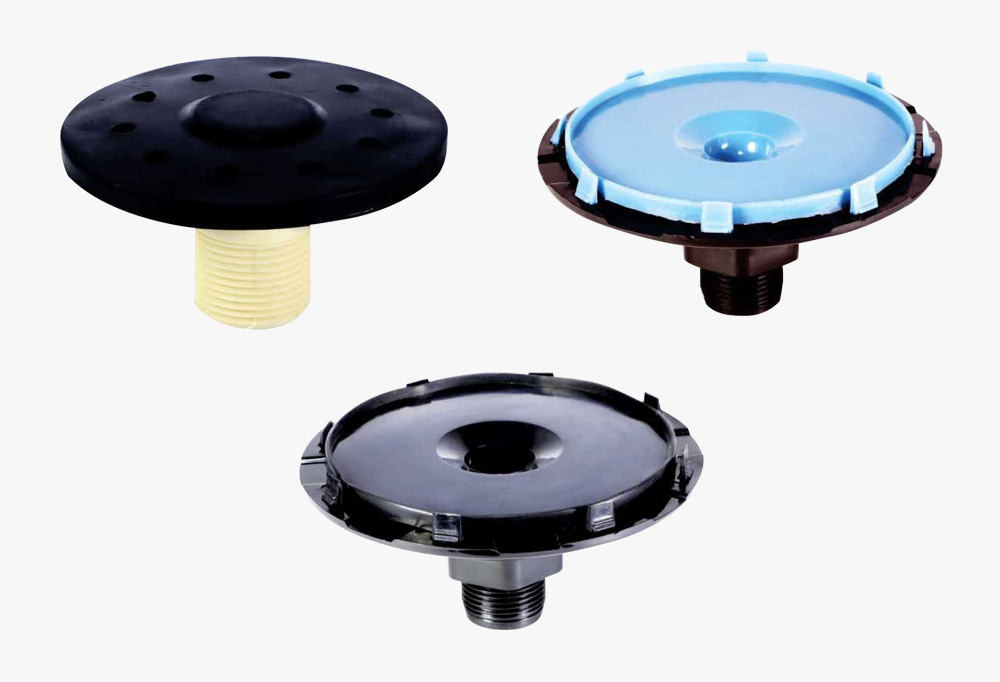

However, there are two different types of bubble diffusers: fine bubble and coarse bubble diffusers.

Though fine bubble diffusers and coarse bubble diffusers both work through bubble aeration but there are few distinguishing features of their design and function.

Both diffusers come in different diameters and sizes depending on the requirement of aeration required.

Fine bubble diffusers produce a smaller-diameter bubble for the aeration process. These bubbles typically measure 1 to 3 mm in diameter. This fine bubble aeration usually provides 2% or more Standard Oxygen Transfer Efficiency (SOTE) during aeration.

Coarse air bubble diffusers, produce a larger diameter of bubble to displace and mix the wastewater effectively. Coarse bubble aeration typically provides 1% or less Standard Oxygen Transfer Efficiency (SOTE) during aeration.

The main principle behind using fine bubble diffusers versus coarse bubble diffusers is that smaller bubbles result in more bubble surface area per unit volume and greater oxygen transfer exchange.

Fine bubble aerators provide enhanced aeration and efficiency, while coarse bubble aerators excel at mixing and increasing the level of dissolved oxygen.

Fine bubble diffusers increase the treatment efficiency and oxygen transfer, thus helps in reducing the power cost as well.

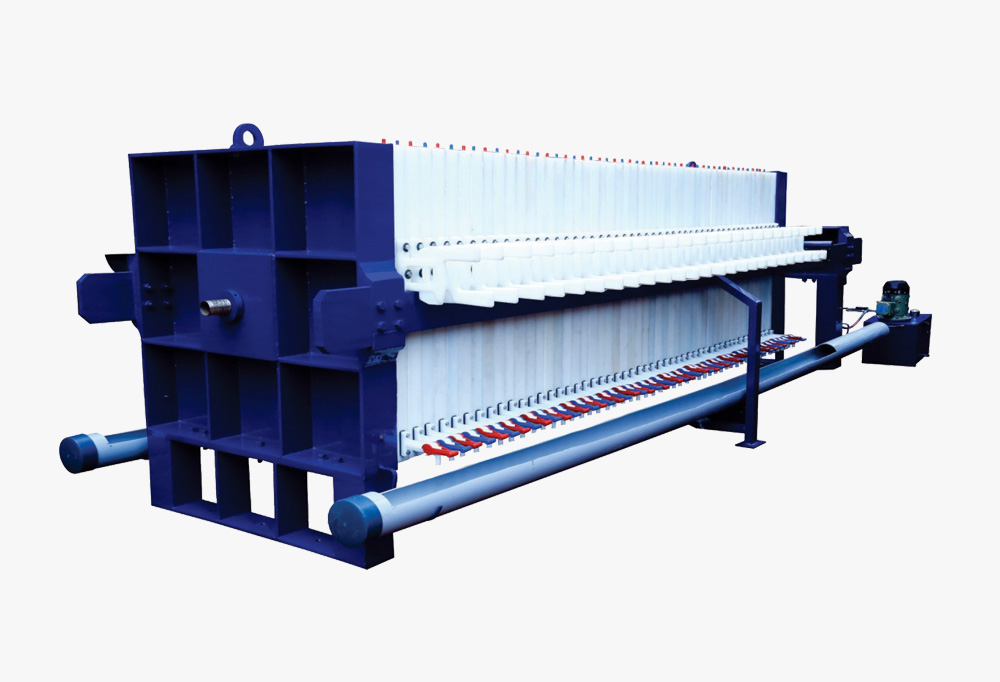

Activated sludge aeration tanks are the largest applications for diffused aeration system. Air diffusion equipments are considered to be the heart of activated sludge process and are suppose to be the largest energy users with plant operations.

FSC India.

FSC India.