Contact Us

+91 81096 09900

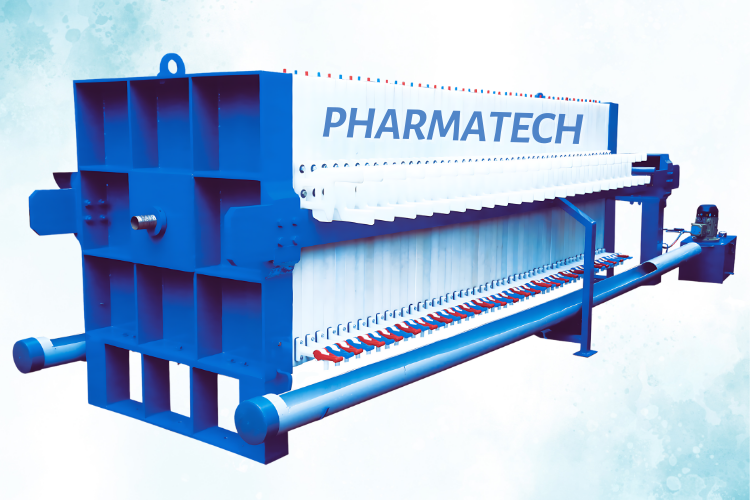

Filter Press Machine Manufacturers In India

CAST IRON / MILD STEEL

12" TO 48" / SS 304/PP

MANUAL, RATCHED GEAR, HAND HYDRAULIC AND POWER HYDRAULIC

UPTO 7 kg/cm2

PP/NYLON/ POLYESTER/ COTTON

UPTO 60 C

Filter Press Machine Manufacturers in India: A Comprehensive Guide by Vasu Pharmatech

In industries like pharmaceuticals, chemicals, food processing, and wastewater treatment, separating solids from liquids is a crucial step. Filter press machines are essential tools for this task, offering efficient and cost-effective solutions. As a leading filter press machine manufacturer in India, Vasu Pharmatech is committed to providing high-quality equipment tailored to diverse industrial needs.

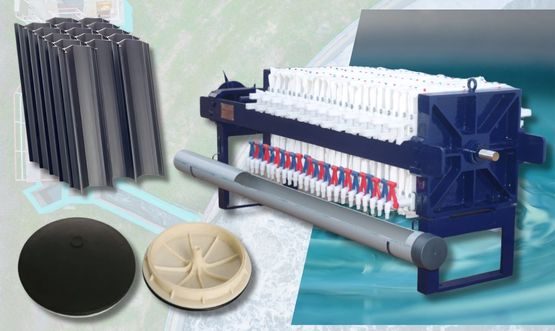

Understanding Filter Press Machines

A filter press machine separates solids and liquids using pressure filtration. The process involves pumping a slurry into the machine, where it is dewatered under pressure. Each filter press is designed based on the volume and type of slurry to be processed.

Types of Filter Press Machines

1. Sludge Filter Press

Designed specifically for sludge dewatering, these machines are vital in wastewater treatment plants. They efficiently reduce the moisture content of sludge, making disposal easier and more environmentally friendly.

2. Hydraulic Filter Press

Hydraulic filter presses use hydraulic pressure to compress the filter plates, ensuring effective dewatering. They are suitable for applications requiring high pressure and are commonly used in chemical and pharmaceutical industries.

3. Manual Filter Press

Ideal for small-scale operations, manual filter presses are cost-effective and easy to operate. They are suitable for industries with lower volume requirements.

4. Automatic Filter Press

These machines offer automated plate shifting and cake discharge, reducing manual intervention and increasing efficiency. They are suitable for large-scale operations requiring continuous processing.

Key Features of Vasu Pharmatech Filter Press Machines

obust Construction: Made with high-quality materials to ensure durability and longevity.

Customizable Sizes: Available in various sizes to meet specific industrial requirements.

Efficient Filtration: Designed to provide optimal solid-liquid separation with minimal energy consumption.

User-Friendly Operation: Equipped with intuitive controls for ease of use.

Applications Across Industries

Filter press machines are versatile and find applications in various industries:

Pharmaceuticals: For purifying active ingredients and intermediates.

Chemicals: To separate chemical compounds and recover valuable solids.Food and Beverage: For clarifying juices, wines, and other beverages.

Textiles: To treat dye wastewater and recover pigments.

Mining: For dewatering mineral concentrates and tailings.

Addressing Common User Concerns

1. Efficiency and Performance

Vasu Pharmatech’s filter press machines are engineered for high efficiency, ensuring maximum solid recovery and minimal moisture content in the filter cake.

2. Maintenance and Durability

Our machines are designed for easy maintenance, with readily available spare parts and comprehensive support services.

3. Cost-Effectiveness

We offer competitive pricing without compromising on quality, ensuring a high return on investment for our clients.

What Our Clients Say About Us

PP Filter Press

Vasu’s PP Filter Press gave us consistent output with zero downtime. Quality is better than other vendors.

Sanjay Patel

MBBR Media

We switched to Vasu’s MBBR Media in our ETP plant. Biofilm grew faster and media remained stable under load.

Neeraj Saini

Tube Deck Media

Tube Deck Media from Vasu reduced our settling time and sludge issues. Good performance in compact STPs.

Pooja Trivedi

Coarse Bubble Diffuser

Coarse Bubble Diffuser gave even air distribution. Setup was quick and it’s been running well for over a year.

Manish Goyal

Fine Bubble Diffusers

We installed Fine Disc Diffusers in our plant. Noticed better oxygen levels and lower energy use immediately.

Anisha Roy

Tube Settler Media

We trust Vasu for Tube Settler Media. The material quality is great and works efficiently even in high TSS.

Nisha Bhandari

PP Filter Press

We’ve been using PP Filter Press from Vasu for 2+ years. Strong build, smooth performance, and zero leakage issues.

Ramesh Verma

MBBR Media

Vasu’s MBBR Media helped improve our STP output quickly. No clogging, fast biofilm growth, and great durability.

Ankit Sharma

Tube Deck Media

After installing their Tube Deck Media, settling improved instantly. Easy to handle and works well in clarifiers.

Meena Desai

Comparing Filter Press Machine Types

| Feature | Manual Filter Press | Hydraulic Filter Press | Automatic Filter Press |

|---|---|---|---|

| Operation | Manual | Semi-Automatic | Fully Automatic |

| Suitable for | Small-scale | Medium-scale | Large-scale |

| Maintenance | Low | Moderate | Low |

| Initial Investment | Low | Moderate | High |

| Processing Speed | Slow | Moderate | Fast |

Choosing the Right Filter Press Machine

When selecting a filter press machine, consider the following factors:

Volume of Slurry: Determine the daily processing volume to choose the appropriate machine size.

Nature of Slurry: Analyze the solid content and viscosity to select the suitable filter media and press type.

Automation Needs: Assess the level of automation required based on labor availability and process complexity.

Budget Constraints: Balance the initial investment with long-term operational costs to ensure cost-effectiveness.

Why Choose Vasu Pharmatech?

Expertise: With years of experience, we understand the unique needs of various industries.

Quality Assurance: Our machines undergo rigorous testing to ensure top-notch performance.

Customer Support: We provide comprehensive after-sales support, including installation, training, and maintenance services.

Customization: We offer tailored solutions to meet specific industrial requirements.

Environmental Benefits of Using Filter Press Machines

In today’s world, industries are increasingly focusing on sustainability and eco-friendly practices. Filter press machines play a vital role in reducing environmental impact.

Waste Minimization: These machines help reduce the volume of waste by extracting excess water from sludge, making disposal easier and more environmentally friendly.

Water Recycling: The filtered water can often be reused in industrial processes, reducing the dependency on freshwater sources.

Compliance with Regulations: Efficient sludge management helps industries stay compliant with environmental norms and avoid penalties.

Energy Efficiency: Modern filter press systems are designed to consume less power while delivering high performance, reducing the carbon footprint.

At Vasu Pharmatech, we design filter press machines that not only perform exceptionally but also contribute to greener industrial practices. Our goal is to support industries in achieving both operational efficiency and environmental responsibility.

Conclusion

Filter press machines are a smart and essential choice for industries that want to manage sludge and wastewater efficiently. Whether you are looking for a sludge filter press, hydraulic filter press, or simply exploring the filter press machine price, it’s important to invest in reliable technology. A well-chosen filter press saves time, reduces waste, and helps meet environmental rules. It also lowers overall costs in the long run by improving water reuse and reducing disposal efforts.

At Vasu Pharmatech, we take pride in being one of the top filter press machine manufacturers in India. Our machines are built with quality, durability, and user needs in mind. From advanced designs to after-sales support, we offer complete solutions to help industries run smoothly. If you’re looking for the best press filter machine with high performance and competitive pricing, Vasu Pharmatech is here to help. Let us support your business with technology that’s efficient, cost-saving, and future-ready.

FAQ

A filter press machine is used to separate solids from liquids in industries like wastewater treatment, chemicals, and pharmaceuticals. It works by using pressure to push liquid through filter cloths, leaving solid cake behind.

Indian manufacturers like Vasu Pharmatech offer high-quality machines at competitive prices. They provide local service support, quick delivery, and custom designs to suit Indian industries and global needs.

You can find different types such as sludge filter press, hydraulic filter press, and automatic filter press. Each is made for different levels of automation, pressure handling, and industrial use.

The filter press machine price depends on size, type, and material. Get a free quote from trusted companies like Vasu Pharmatech who offer fair pricing and tailored solutions based on your industry needs.

Vasu Pharmatech stands out for quality, innovation, and customer satisfaction. With years of experience as a filter press machine manufacturer in India, we deliver reliable machines that are easy to use and maintain.

About The Author

Lalit Nankani

Managing Partner, Vasu Pharmatech

Lalit Nankani has over 12 years of experience in the filtration and water treatment industry. He leads Vasu Pharmatech, a trusted name in making PP Filter Press Systems, MBBR Filter Media, and other filtration products.

Under his leadership, the company has delivered high-quality solutions to many industries like pharmaceuticals, chemicals, food and beverage, textiles, and wastewater treatment. Lalit believes in providing strong, easy-to-use, and cost-effective systems that help businesses clean and reuse water.

In-house Manufacturing Images

Reviews and Ratings

We certify that M/s. Vasu Pharmatech, located at 66B, Pocket AD Shalimar Bagh, Delhi-110088, supplied us with a Pharmatech filter press for our 275 KLD ETP plant at M/s. Asian Colour Coated Ispat Ltd. in Bawal, Dist: Rewari (Hr.). The plant was started in January 2018 and is still working well. The product and its performance have been satisfactory up to now.

ASIAN COLOUR COATED ISPAT LIMITED

Filter Press Machine Manufacturers In India , Sludge Filter Press Manufacturers In India, Hydraulic Filter Press Manufacturers In India, Filter Press Machine Price, Press Filter Machine

Filter Press Machine Manufacturers In India , Sludge Filter Press Manufacturers In India, Hydraulic Filter Press Manufacturers In India, Filter Press Machine Price, Press Filter Machine