Contact Us

+91 81096 09900

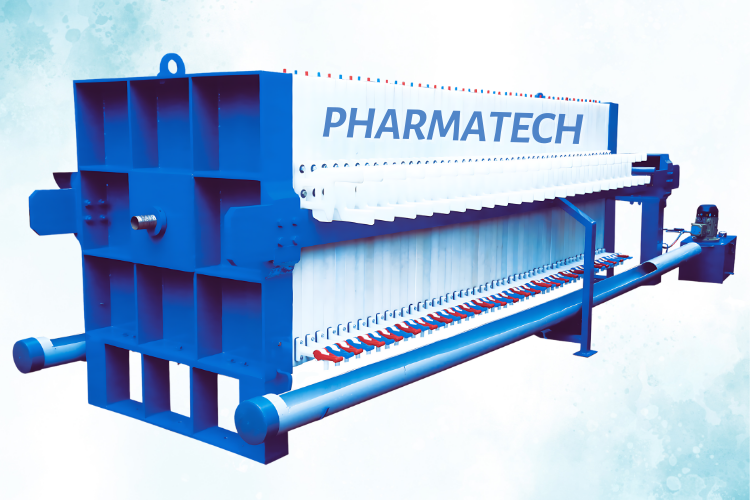

Filter Press

CAST IRON / MILD STEEL

12" TO 48" / SS 304/PP

MANUAL, RATCHED GEAR, HAND HYDRAULIC AND POWER HYDRAULIC

UPTO 7 kg/cm2

PP/NYLON/ POLYESTER/ COTTON

UPTO 60 C

Filter Press – A Simple Guide to an Essential Machine in Wastewater Treatment

Filter press is a powerful and widely used machine in many industries for separating solids from liquids. Whether it’s in chemical plants, pharmaceutical companies, food processing, mining, or wastewater treatment, a filter press machine plays a key role in keeping processes clean and efficient.

In this guide by Vasu Pharmatech, we’ll explain what a filter press is, how it works, types of filter presses (like the popular PP filter press), its applications, benefits, and why you should choose the right filter press manufacturer or supplier in India.

What Is a Filter Press?

A filter press is a type of equipment used to remove solids from liquids. It works on a simple principle: pressure is used to push liquid through a filter cloth, and the solid parts are left behind.

The result?

- Clear liquid (called filtrate)

- Solid cake (called filter cake)

It’s like squeezing juice from crushed fruit – the juice comes out, and the pulp stays behind.

How Does a Filter Press Machine Work?

Here’s a step-by-step look at how a filter press machine operates:

1. Filling Stage

Slurry (liquid with suspended solids) is pumped into the press. The slurry fills all the filter chambers.

2. Filtration Stage

Pressure is applied. Liquid passes through the filter cloth, but solids are trapped inside the chamber.

3. Cake Formation

As more slurry enters, solids build up and form a filter cake. The cake grows thicker as filtration continues.

4. Cake Release

Once the chamber is full, the press opens, and the solid cake is discharged. The machine is ready for the next cycle.

Types of Filter Presses

There are different types of filter press machines, depending on the need, size, and type of material to be filtered.

PP Filter Press (Polypropylene Filter Press)

This is one of the most common types today. The plates are made from polypropylene, which is lightweight, chemical-resistant, and strong. It’s ideal for chemical and pharma industries.

Hydraulic Filter Press

Uses hydraulic pressure to close the plates. Suitable for high-pressure applications.

Manual Filter Press

Operated by hand. Best for small plants or low-budget applications.

Automatic Filter Press

Fully automated. Saves labor and time. Perfect for industries with large volume and continuous operation.

Main Parts of a Filter Press Machine

To understand better, let’s break down the main parts of a filter press:

| Part | Function |

|---|---|

| Frame | Supports the whole system |

| Filter Plates | Hold the filter cloths and create chambers |

| Filter Cloth | Filters the liquid from solid |

| Hydraulic System | Applies pressure to close the plates |

| Pump | Pushes the slurry into the machine |

Each of these parts must be of high quality for the press to perform well and last long.

Applications of Filter Press Machines

Filter presses play an important role across a wide range of industries due to their ability to separate solids from liquids effectively.

Some of the main sectors that rely on this equipment include:

- Pharmaceuticals – Used for purifying liquids and recovering valuable compounds

- Chemicals – Helps eliminate unwanted solid particles during production

- Food and Beverage – Commonly used for clarifying juices, processing sugar, and refining oils

- Water Treatment Facilities – Removes sludge and other solid residues

- Mining Operations – Separates useful minerals from slurry waste

- Oil Processing – Supports clarification in edible and industrial oil refining

Whether it’s for processing raw inputs or cleaning up discharge, this separation technology is a reliable part of modern industrial systems.

Benefits of Using a Filter Press Machine

Using a filter press has several advantages that make it a popular choice across industries:

1. High Efficiency

Filter presses remove more solids compared to other methods. You get clearer water and drier solids.

2. Cost Saving

By recovering more materials and reducing waste disposal costs, companies save money over time.

3. Compact Design

Takes up less space. Even a small filter press can handle a large amount of slurry.

4. Reusable Filter Cloth

Filter cloths can be cleaned and reused, reducing operating costs.

5. Custom Sizes Available

Available in many sizes – from small units to large industrial machines.

Why PP Filter Press Is So Popular

PP filter press machines are widely used today because polypropylene is:

- Non-reactive to most chemicals

- Lightweight but strong

- Easy to clean

- Durable and long-lasting

They are the preferred choice for pharmaceutical and chemical industries where purity and reliability are key.

Choosing the Right Filter Press Manufacturers and Suppliers in India

India’s demand for filter press machines is rising, thanks to growth in industries like pharmaceuticals, chemicals, food processing, and wastewater treatment. But not every supplier delivers the same level of quality. Choosing the right manufacturer can make a big difference in your plant’s performance and maintenance costs.

Here are five key things to check before selecting a filter press manufacturer or supplier in India:

1. Experience and Reputation

Work with companies that have years of hands-on experience and a strong reputation in the field. A proven track record means they understand common challenges and offer dependable solutions.

2. Customization Options

Every industry has different needs. The best manufacturers offer custom-built filter press machines, including various plate sizes, frame materials, and filter cloth types to suit your process.

3. Quality of Materials

Check if the equipment is made from virgin-grade PP, stainless steel, or other durable materials. Strong frames, leak-proof plates, and efficient hydraulic systems are critical for long-term use.

4. After-Sales Support

Your filter press is just the beginning. Good suppliers provide installation help, operator training, spare parts, and responsive customer service.

5. Certifications and Compliance

Reliable manufacturers follow ISO guidelines and other quality standards. This ensures your machine is safe, efficient, and ready for industrial use.

Tips for Operating a Filter Press Machine

Operating a filter press is simple, but following best practices will increase life and performance:

- Clean filter cloths regularly

- Don’t overload with solids

- Keep an eye on hydraulic pressure

- Use the correct feed pump

- Inspect parts every month

A well-maintained filter press machine will perform better and last longer.

How to Improve Filtration Performance

Want to get better results from your filter press?

Try these:

- Use high-quality filter cloths matched to your slurry

- Precoat cloths with a filter aid (like activated carbon or lime)

- Avoid over-tightening plates (can damage cloths)

- Monitor cake dryness – adjust cycle time as needed

- Use proper feed pressure and flow rate

Our experts at Vasu Pharmatech help clients optimize their filter press setup for better efficiency and lower running costs.

Why Choose Vasu Pharmatech for Your Filter Press Needs?

At Vasu Pharmatech, we are more than just filter press manufacturers — we are complete solution providers.

Here’s why industries across India choose to work with us:

- Wide Range of Machines – Including PP filter presses, hydraulic, manual, and automatic models

- Custom Design – Engineered to match your specific plant layout and process requirements

- High-Quality Materials – Built using virgin-grade materials for long-term durability and reliability

- Cost-Effective Pricing – High performance without unnecessary costs

- Pan-India Support – Timely delivery and responsive service, wherever your facility is located

- Trusted by Multiple Sectors – Serving pharmaceuticals, food and beverage, chemicals, wastewater treatment, and more

Whether you’re operating a small plant or a large industrial setup, Vasu Pharmatech delivers the right filter press solution tailored to your needs.

Conclusion

Choosing the right filtration system is essential for smooth and efficient operations across many industries. Whether you require a simple setup or a fully automated unit, investing in the right equipment can help you reduce downtime, save on energy, and minimize maintenance issues.

At Vasu Pharmatech, we go beyond just supplying equipment — we aim to be your long-term technology partner. With deep experience serving sectors like pharmaceuticals, food production, chemicals, and wastewater management, we offer solutions tailored to your unique process needs.

If you’re searching for dependable, cost-effective filtration options designed for long-term performance, our team is here to support you. Connect with us today and let’s find the best fit for your operation.

FAQ

A filter press is a machine that separates liquids from solids. It works by using pressure to push liquid through special plates, leaving the solid material behind. This helps make the liquid cleaner and easier to reuse or dispose of.

Manual filter presses need someone to operate them by hand, which takes more time and effort. Automatic models handle most of the process on their own, making them faster and better for bigger setups.

PP is a plastic material that’s strong and doesn’t rust or react with chemicals. It’s a smart choice because it lasts long and is easy to clean, especially in places where harsh liquids are filtered.

You’ll need to think about how much material you want to filter, what kind of waste you’re dealing with, and how often the machine will be used. It’s a good idea to get help from someone who understands these machines well.

They’re common in places like factories, water treatment plants, and food or chemical processing units. Any place that needs to clean up liquid waste or recycle water can benefit from using one.

In-house Manufacturing Images

Reviews and Ratings

We certify that M/s. Vasu Pharmatech, located at 66B, Pocket AD Shalimar Bagh, Delhi-110088, supplied us with a Pharmatech filter press for our 275 KLD ETP plant at M/s. Asian Colour Coated Ispat Ltd. in Bawal, Dist: Rewari (Hr.). The plant was started in January 2018 and is still working well. The product and its performance have been satisfactory up to now.