Contact Us

+91 81096 09900

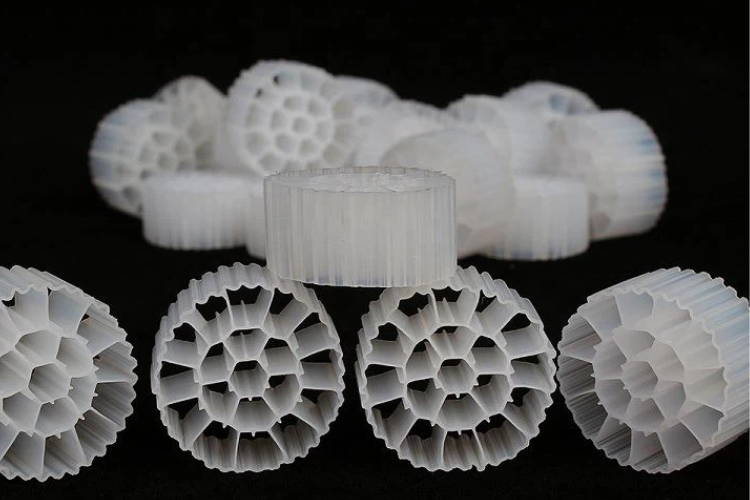

MBBR

12 x 25 mm

19

>5OO m2/m3

0.94 - 0.96 gm/cm3

15% to 65%

3-15 Days

VIRGIN HDPE

Choosing the Right MBBR Media for Wastewater Treatment – A Guide by Vasu Pharmatech

At Vasu Pharmatech, we know that treating wastewater in the right way is very important. Whether it’s a factory that makes medicines, food, clothes, or chemicals, proper wastewater treatment protects the environment and keeps operations running smoothly. That’s why we recommend MBBR (Moving Bed Biofilm Reactor) technology. It is modern, effective, and cost-saving.

In this article, we’ll explain what MBBR is, how it works, what types of MBBR media are available, and how you can choose the best one for your needs. We’ve used very simple English so that everyone can understand, no matter your background.

What is MBBR Technology?

MBBR stands for Moving Bed Biofilm Reactor. It is a type of wastewater treatment system that uses small plastic pieces (called media) to grow bacteria. These bacteria eat the organic waste in the water.

Here’s how it works:

- Wastewater enters the aeration tank.

- Air is blown into the tank using diffusers.

- Plastic media float in the tank and move around because of the air.

- Good bacteria grow on the surface of the media.

- These bacteria eat the harmful materials in the water.

This system is better than traditional treatment methods because it is more efficient and takes up less space.

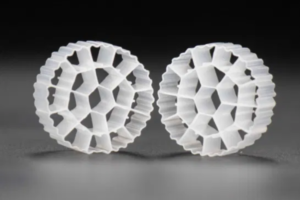

What is MBBR Media?

MBBR media are small pieces of plastic, often shaped like wheels or small tubes. Their job is to give bacteria a place to live and grow. The surface of each media provides area for bacteria to stick to and grow into biofilm.

More surface area = more bacteria = better cleaning of the water.

The media float in the water, and as air is pushed through the tank, they keep moving. This movement ensures that the bacteria get oxygen and stay healthy. It also keeps the media from clumping together.

Why Use MBBR Technology?

There are many reasons why industries and municipal bodies use MBBR systems:

1. Space Saving

MBBR systems need smaller tanks because they are more efficient. This saves land and building costs.

2. Easy to Operate

MBBR systems are mostly self-controlled. You don’t need highly trained operators to manage them.

3. Low Maintenance

These systems don’t have many moving parts. So, there is less wear and tear, and you spend less on repairs.

4. Handles Fluctuations Well

If the wastewater suddenly becomes stronger or more polluted, MBBR can still handle it.

5. Energy Saving

Because of efficient media movement, less air is needed. That means lower electricity bills.

6. Scalable

You can easily increase the system size if your business grows. Just add more media or tanks.

Types of MBBR Bio Media Offered by Vasu Pharmatech

At Vasu Pharmatech, we help you choose the best media for your plant. Here are the main types:

1. Wheel-Shaped Media

- Looks like a wheel with spokes

- Large surface area

- Allows good water and air flow

- Commonly used in all kinds of plants

2. Chip-Type Media

- Thin flat plastic chips

- Flexible and lightweight

- Very high protected surface area

- Best for high-efficiency applications

3. Tube or Cylindrical Media

- Long, round, hollow

- Easy to stay floating

- Can be at risk of clogging if not cleaned

4. Sponge Media

- Soft, porous structure

- Holds a lot of bacteria

- Can get damaged faster

5. Coin-Shaped Media

- Thin discs with open sides

- Great water movement

- Less chance of blocking

Each type has its own benefits. The choice depends on your plant’s load, type of waste, and budget.

How to Choose the Right MBBR Media

Choosing the best media for your system is not just about shape or size. Here are some key things to look for:

1. Surface Area

More surface area means more space for bacteria. But too much open area can lead to clogging. Choose media with a good balance.

2. Density

Good media should be slightly heavier than water but not too heavy. This helps them float and move properly.

3. Durability

High-quality media lasts longer. It resists wear and tear and doesn’t break easily.

4. Material Quality

Always choose media made from virgin plastic like HDPE or polyethylene. Recycled plastic is weaker and can degrade faster.

5. Air Demand

Some media need more air to move. That means more power. Choose efficient media to save energy.

6. Bacteria Compatibility

Some bacteria need slow oxygen supply (anaerobic), others need more oxygen (aerobic). Different media work better for different types.

MBBR Media Sizes and Colors

MBBR media come in different sizes. Common sizes include:

- 10 mm x 7.5 mm

- 25 mm x 10 mm

- 25 mm x 8 mm

The best size depends on your tank size and the type of waste.

Colors are usually white, but we also offer red, green, blue, and black. These do not affect performance but can help with sorting or identification.

How to Calculate the Amount of Media You Need

Step 1: Know the Flow and Load

Let’s say your plant has a flow of 500 m³/day. The incoming BOD is 300 mg/L and you want to reduce it to 30 mg/L.

That means your organic load = 500 x (300 – 30) = 135,000 mg/day = 135 kg/day

Step 2: Know the Media Capacity

Let’s say the media you choose removes 1.5 kg BOD per m³ per day.

So, you need 135 ÷ 1.5 = 90 m³ of media.

Make sure the tank can hold that much and still allow space for water and air.

Why Choose Vasu Pharmatech MBBR Media?

We take pride in delivering high-quality MBBR media that meet international standards. Here’s why customers trust us:

✔ Energy Efficient

Our media is designed to move easily with low air input. This reduces blower costs.

✔ Custom Shapes and Sizes

We manufacture media in many designs. If needed, we can create custom shapes for your specific needs.

✔ Strong and Durable

Made from virgin raw material, our media last long and resist damage.

✔ High Surface Area

Our designs maximize biofilm growth without clogging.

✔ Expert Support

We don’t just sell media. We offer full support — from design to setup to after-sales service.

Specialities of Vasu Pharmatech

At Vasu Pharmatech, we believe that the best results come from smart design and full system integration. That’s why:

At Vasu Pharmatech, we believe that the best results come from smart design and full system integration. That’s why:

We keep our design in-house – It gives us complete control over quality and lets us innovate faster to meet your specific needs.

We always prioritize energy efficiency – When selecting MBBR media, we focus on low-resistance designs that reduce air demand and save on power costs.

We design integrated systems – Media and diffusers are selected and optimized together. This ensures smoother operation, better oxygen transfer, and higher treatment efficiency.

These principles are part of everything we build and supply. It’s not just about selling media — it’s about engineering better outcomes.

Conclusion

Choosing the right MBBR media is one of the most important decisions when setting up or upgrading a wastewater treatment plant. The right media helps grow strong biofilm, improves cleaning performance, saves energy, and keeps the system running smoothly for many years. But not all media are the same. The shape, size, material, and surface area all affect how well the system works.

At Vasu Pharmatech, we offer more than just high-quality MBBR media. We bring deep industry knowledge, custom system design, and full support to every project. Our in-house design team ensures that every system we deliver is optimized for efficiency, durability, and energy savings. We carefully select and manufacture each piece of media to ensure maximum biofilm growth without clogging or extra maintenance.

Whether you’re treating water from pharmaceuticals, food processing, textiles, or chemical industries, our MBBR solutions are designed to handle complex loads and strict discharge standards. We also help plants reduce electricity usage by designing systems that work with low-air-demand media and high-efficiency diffusers.

FAQ

MBBR media is used in wastewater treatment systems to grow biofilm (good bacteria) that remove harmful substances from water. It increases the surface area for bacteria to grow and helps clean the water more efficiently.

You should look at factors like surface area, media shape, material quality, and oxygen demand. At Vasu Pharmatech, we help you choose the best MBBR media based on your water type, tank size, and treatment goals.

Yes. MBBR technology can be added to existing tanks in most treatment plants. It’s a great way to improve performance without building a whole new system.

Yes. Good quality MBBR media is designed to move with low air pressure. This means less power is needed for blowers, which saves electricity and reduces your operating cost.

High-quality media like the ones made by Vasu Pharmatech can last 10 years or more. They are made from strong virgin plastic and resist damage, wear, and chemical attack.

Reviews and Ratings

We certify that M/s. Vasu Pharmatech, located at 66B, Pocket AD Shalimar Bagh, Delhi-110088, supplied us with a Pharmatech filter press for our 275 KLD ETP plant at M/s. Asian Colour Coated Ispat Ltd. in Bawal, Dist: Rewari (Hr.). The plant was started in January 2018 and is still working well. The product and its performance have been satisfactory up to now.